INCREASE UPTIME WITH AUTONOMOUS INSPECTION

Collect high-quality inspection data and receive AI-driven insights on critical equipment with the Energy Robotics Platform for autonomous robotic inspection.

Talk To UsCollect high-quality inspection data and receive AI-driven insights on critical equipment with the Energy Robotics Platform for autonomous robotic inspection.

Talk To Us

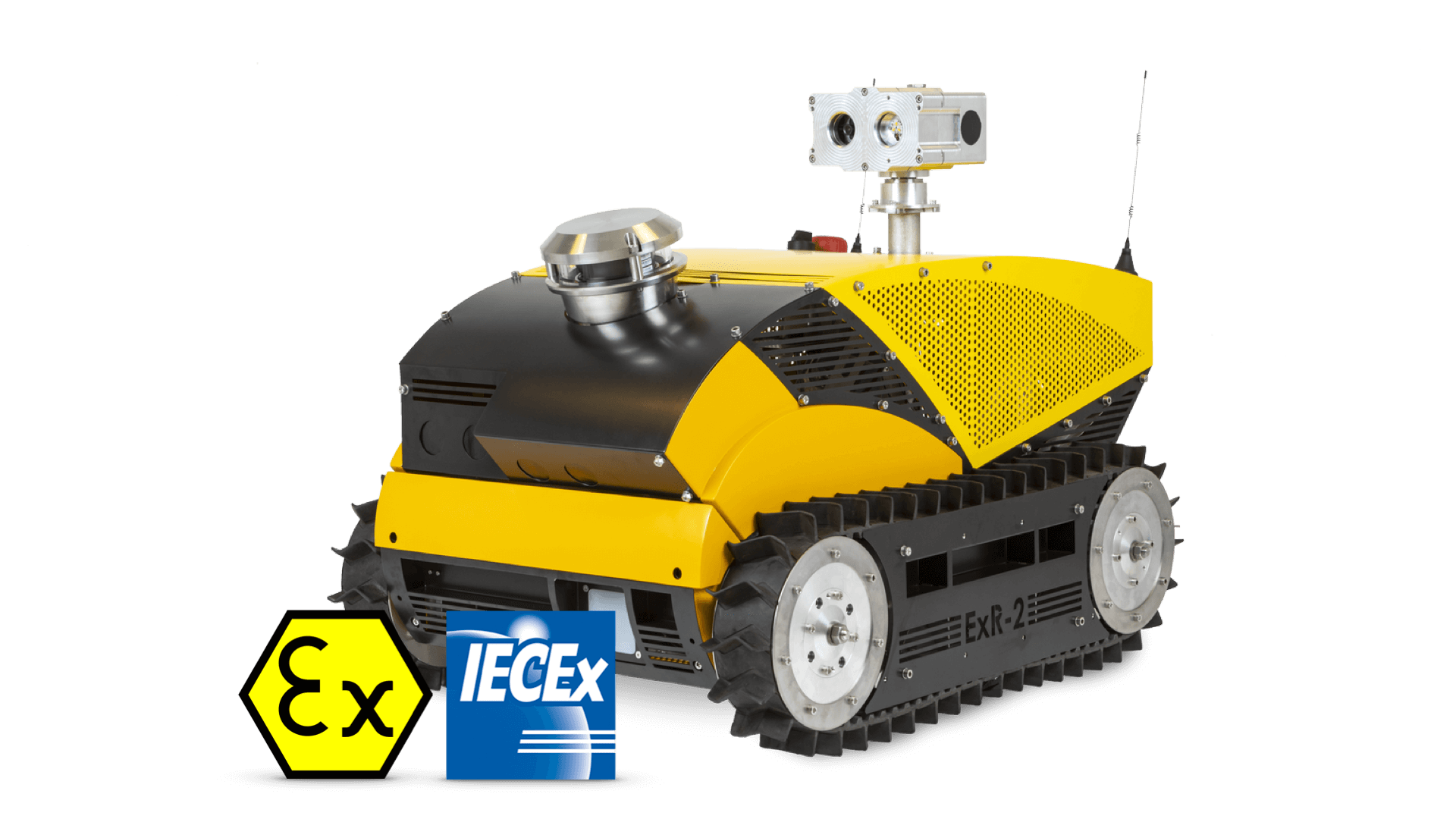

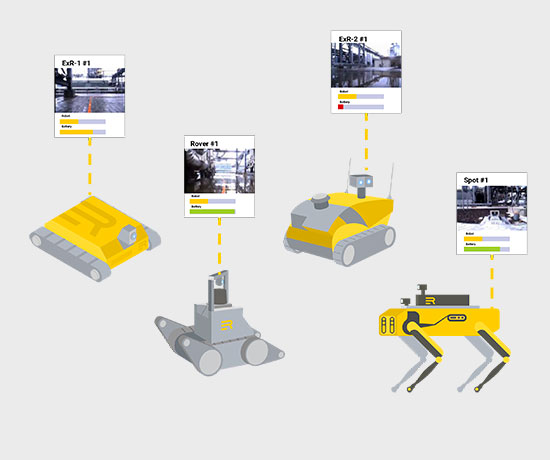

Manage a diverse fleet of tracked and legged robots that reliably monitor plant infrastructure and deliver actionable insights in time, thus preventing costly down-times. Book a free demo for a hands-on experience of autonomous inspection!

START AUTOMATING NOWManage a diverse fleet of robots and drones to collect high-quality site data with no human intervention. What is more, this data is converted into insights and delivered to your fingertips resulting in timely response.

We have brain-powered Spot to consistently and reliably monitor critical equipment at Evonik's chemical facility, and to collect high quality data even in areas that are hard to access for humans. We're thrilled to be collaborating with Evonik in automating inspection tasks and supporting them in ensuring high safety standards.

GO TO CASE STUDY