Inspect remote facilities with Autonomous Robots

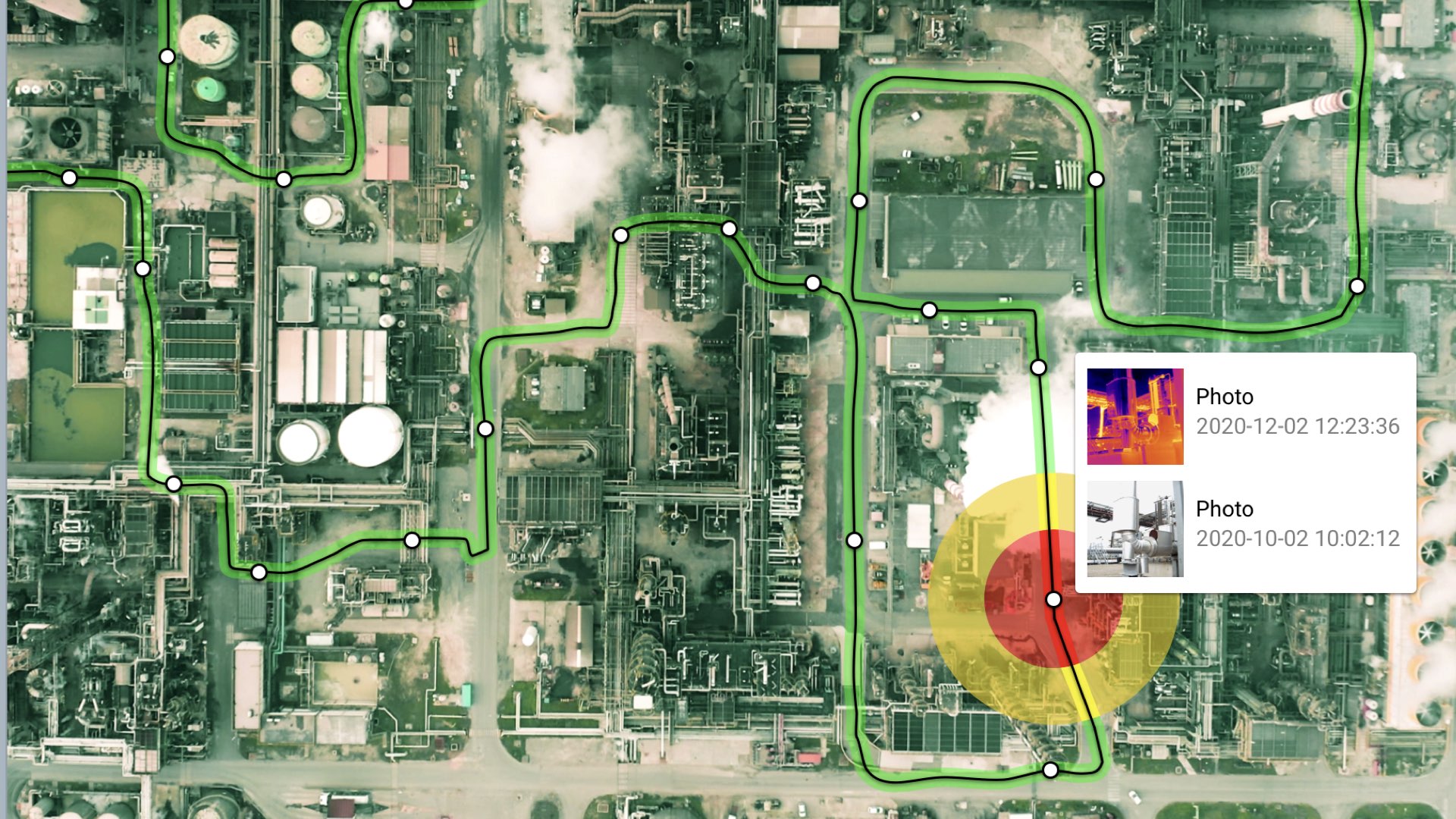

Receive actionable insights from offshore and onshore facilities, refineries, tank fields and processing plants with the Energy Robotics Platform for autonomous robotic inspection.

TALK TO USReceive actionable insights from offshore and onshore facilities, refineries, tank fields and processing plants with the Energy Robotics Platform for autonomous robotic inspection.

TALK TO US

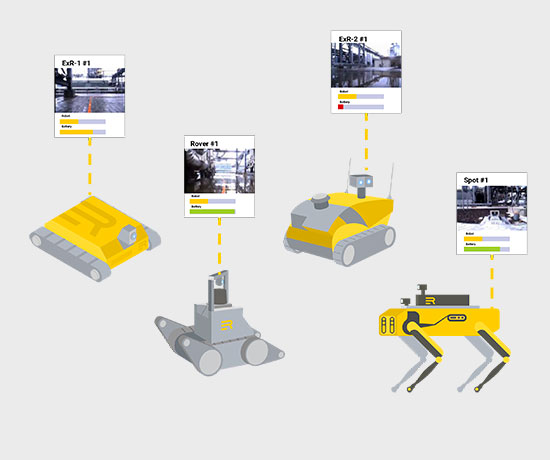

Manage a diverse fleet of robots and drones to collect high-quality site data with no human intervention. What is more, this data is converted into insights and delivered to your fingertips resulting in timely response and reduced downtime.

REQUEST A DEMOManage a diverse fleet of robots and drones to collect high-quality site data with no human intervention. What is more, this data is converted into insights and delivered to your fingertips resulting in timely response.

We are enabling the digitalization of Shell's Tank Farms and contributing to achieve the goal of zero work place accidents through automated drone inspections. Asset owners can now monitor hundreds of inspection points across more than 10 kilometers in just minutes.

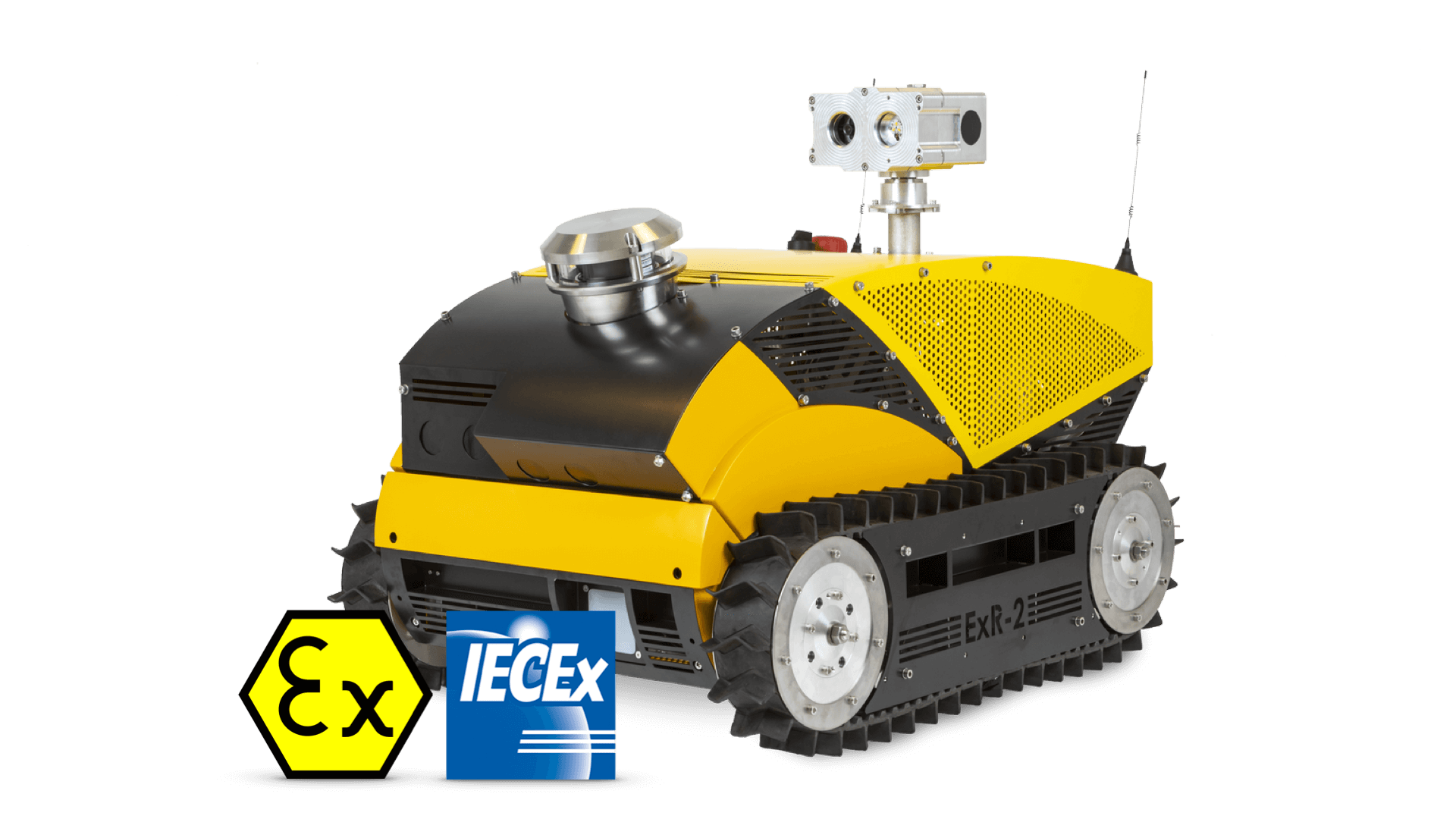

explore DRONE INSPECTIONSHere’s a sneak-peek at how our end-to-end robotics solution is transforming inspection operations at Shell’s oil refineries. Our software enables robots to perform efficiently in potentially explosive ATEX or IECEx environments that are commonly found in the oil and gas industry.

"The robot now fully autonomously takes pictures of the gauges, reads them and sends them to our data historians. So, the end-to-end data flow is already fully automated."