Autonomous Inspection Software platform

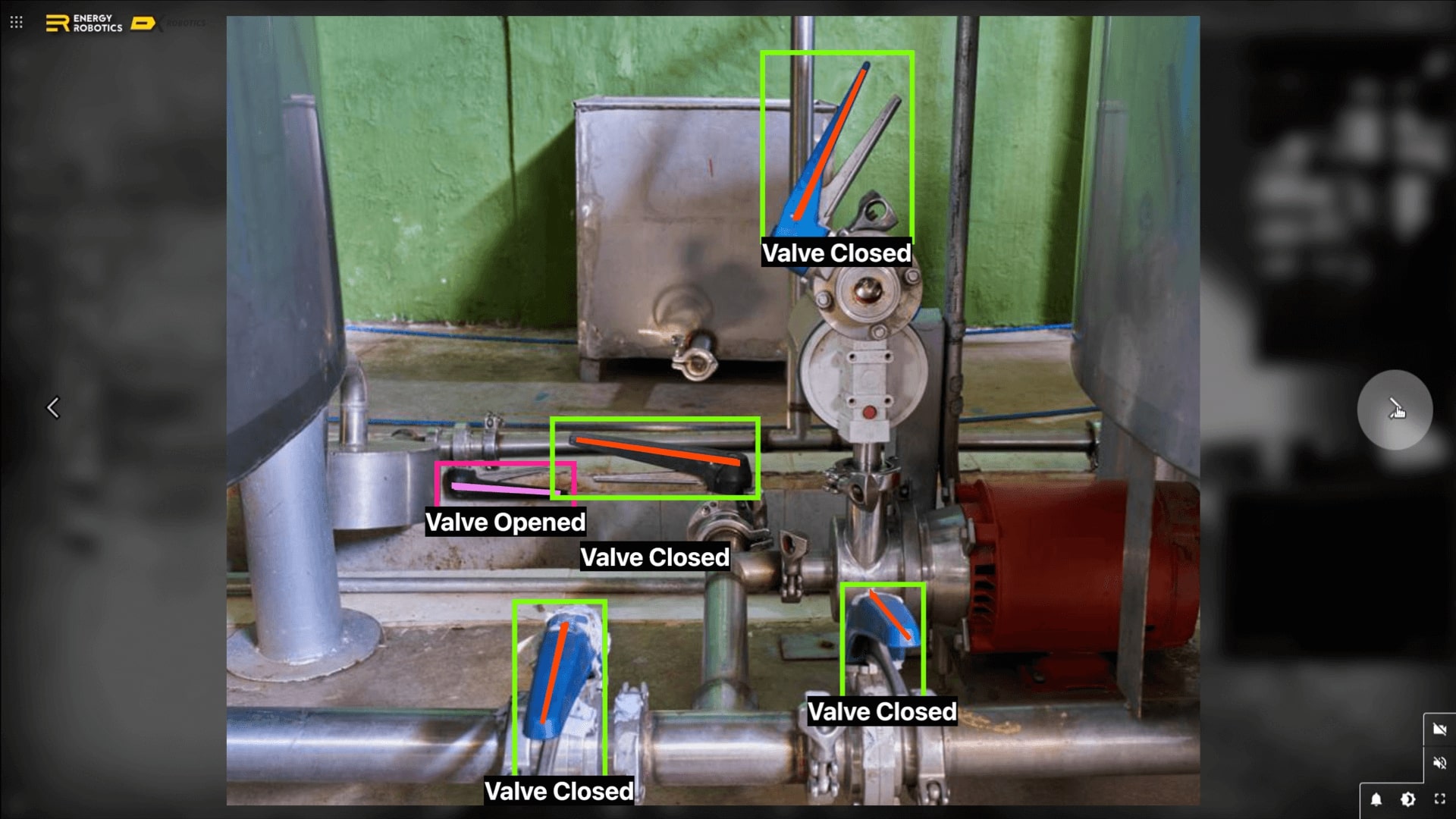

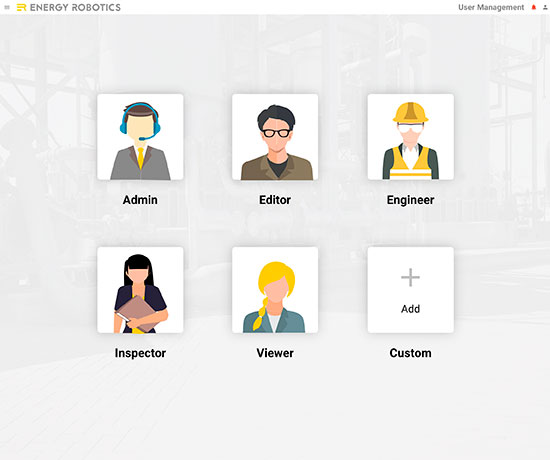

Manage and monitor a fleet of robots, run inspection missions to capture high quality data, easily access inspection reports and derive actionable information through AI-driven analytics, all through one single platform. That’s what we mean by end-to-end solution.

START AUTOMATING NOW