REDUCE DOWNTIME WITH AUTOMATED INSPECTION OF REMOTE SITES

Receive actionable insights and minimize downtime in power production and distribution facilities by deploying robots with the Energy Robotics Platform for autonomous inspection.

TALK TO USReceive actionable insights and minimize downtime in power production and distribution facilities by deploying robots with the Energy Robotics Platform for autonomous inspection.

TALK TO US

.png)

Inspection in power generation and distribution facilities is difficult due to the remoteness of locations, dangerous work environments and rising costs of deployment. Learn how autonomous inspection robots are tackling these challenges to reliably deliver actionable insights, thus reducing downtimes and ensuring steady power supply. Book a free demo for a hands-on experience of autonomous inspection!

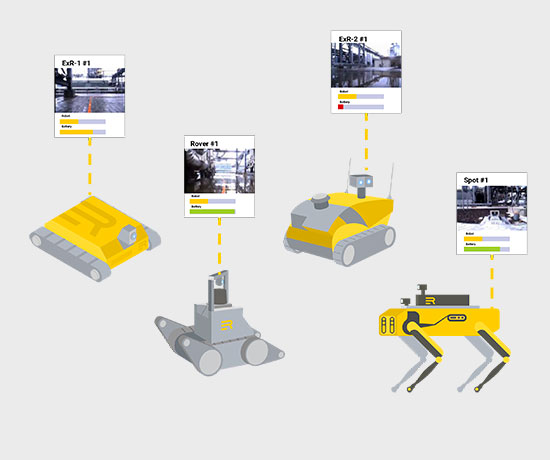

START AUTOMATING NOWManage a diverse fleet of robots and drones to collect high-quality site data with no human intervention. What is more, this data is converted into insights and delivered to your fingertips resulting in timely response.

We're spearheading advancements in the power industry by utilizing autonomous robots within E.DIS's remote substations, thus providing operators with practical data instantly, eliminating onsite commutes and efficiently monitoring vital equipment through regular autonomous inspection rounds.

go to case studyWe are revolutionising inspection at llwerke vkw's hydropower plant in the Austrian Alps.

By automating inspection tasks the energy provider can save on travel expenses and monitor the plant constantly, especially in winter months, when storms might shut mountain roads, making the plant inaccessible.

.png)

"We have successfully tested and are pleased with the various functionalities provided by Energy Robotics, including general inspection of substation technology through reading analog measuring instruments; monitoring basic safety issues; and transmitting data securely."